A Complete DIY Fabric Dyeing Tutorial with Natural Indigo Plant Dye

Indigo plant dye stands apart from any other natural dye. Unlike most, it doesn’t dissolve in water. Instead, it requires a carefully prepared alkaline solution with the oxygen removed before it becomes usable. This unique process makes indigo one of the most fascinating dyes in the world.

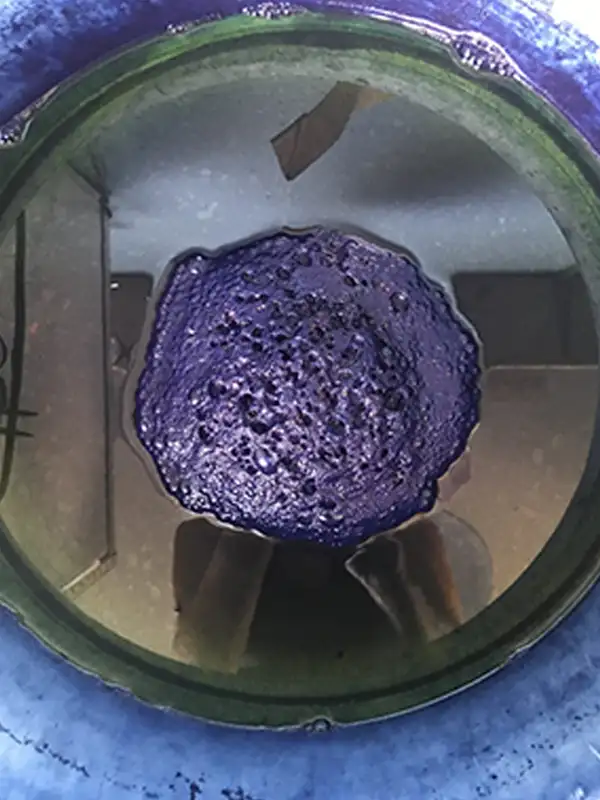

If you are familiar with the indigo dyeing process, you’ll recognise the blue pigment or indigo cakes like the ones you can find right here. But what is the source of this rich blue colour? A plant. One of the most well-known species, Indigofera tinctoria, has been cultivated for thousands of years. The leaves contain a chemical compound called indican, which transforms into vibrant blue dye through extraction and fermentation. Thriving in warm, humid climates, indigo-bearing plants grow abundantly in regions like India, South America, and Japan. However, they are not frost-hardy and require a long growing season.