Block printing is a time-honoured craft that beautifully blends artistry and tradition, with Dabu block printing standing out as one of its most exquisite techniques. Originating from Rajasthan, India, Dabu is a resist-dyeing method that uses a mud paste to create intricate patterns. Skilled artisans hand-carve wooden blocks with detailed designs, which are then stamped onto fabric coated with the mud paste. Once dyed, the areas covered by the paste resist the colour, leaving behind stunning, earthy patterns. This process, repeated for multi-coloured designs, is both labour-intensive and deeply rooted in sustainability, as it uses natural dyes and traditional skills passed down through generations. Dabu block printing embodies the essence of slow fashion, offering a tactile connection to craftsmanship, culture, and the beauty of handmade textiles.

Examples of block printing are thought to stretch all the way back to ancient civilisations.

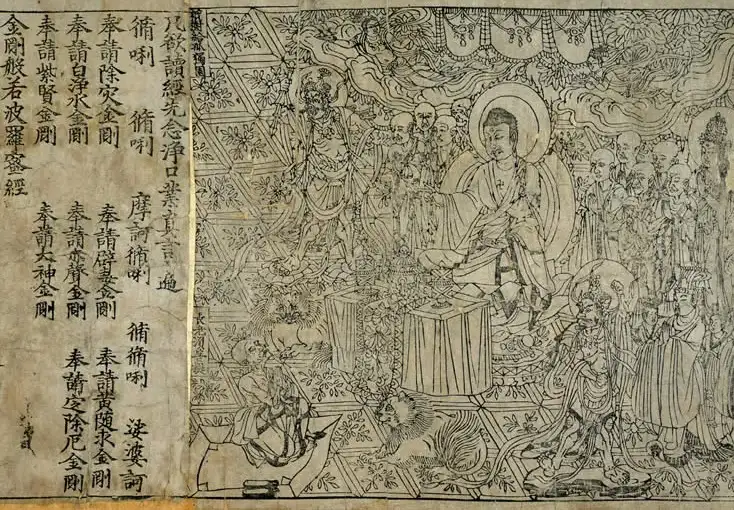

The earliest examples originate from China in the 3rd century, going on to spread through Egypt, Asia, and eventually the rest of the world.

Here you can see one of the earliest examples of block printing: the “Diamond Sutra,” a Buddhist text block printed in China that dates back to 868 CE.

It isn’t difficult to find block printing scattered through history – the technique was used to create everything from religious texts, to calendars, to artwork. Sometimes, you may not even realise when this technique was used!

A great example is the well-known Japanese print “The Great Wave off Kanagawa” by Hokusai, which you can see below alongside a modern replication of the technique similar to the one that would have been used.

A work like this has been reused and reprinted so many times, you may be surprised to find that such an illustrative and intricate print was originally created with woodblock techniques – it just goes to show how versatile this art is!

While the origins are vast, some of the first surviving records of block printed textiles are from India, which is one of the reasons it is known as the epicentre of the technique. The story starts during the Mughal Dynasty, where block printing appeared everywhere from textiles to the Taj Mahal. This was a prosperous time for the textile industry, and the Mughal style and traditions are continued to this day. You might recognise the aesthetic in the repetition of curved shapes, florals, and naturally influenced details in many textile designs.

When the proper dyes and materials are used, block printing is one of the most sustainable patternmaking techniques, making it a great option for slow fashion.

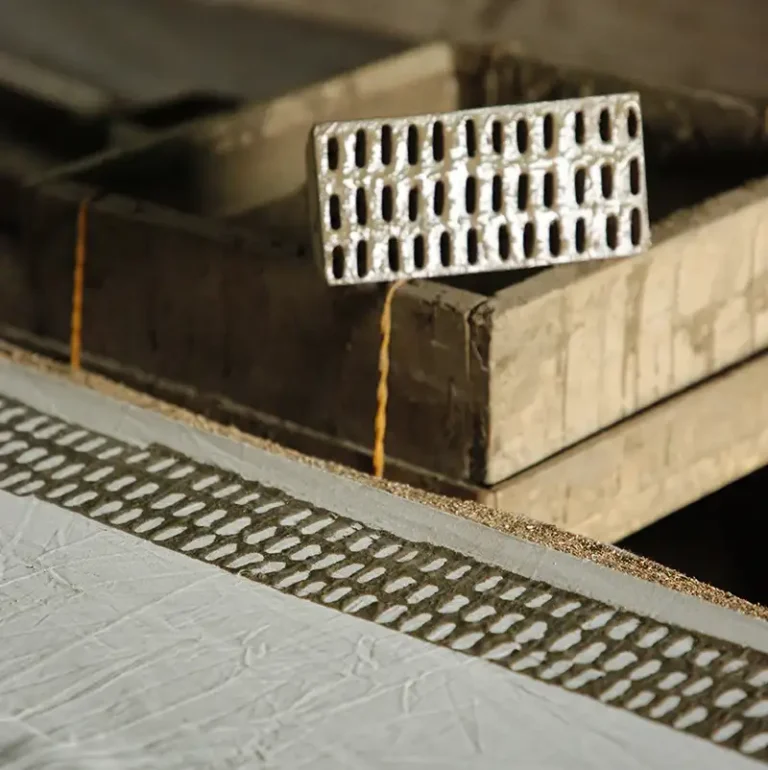

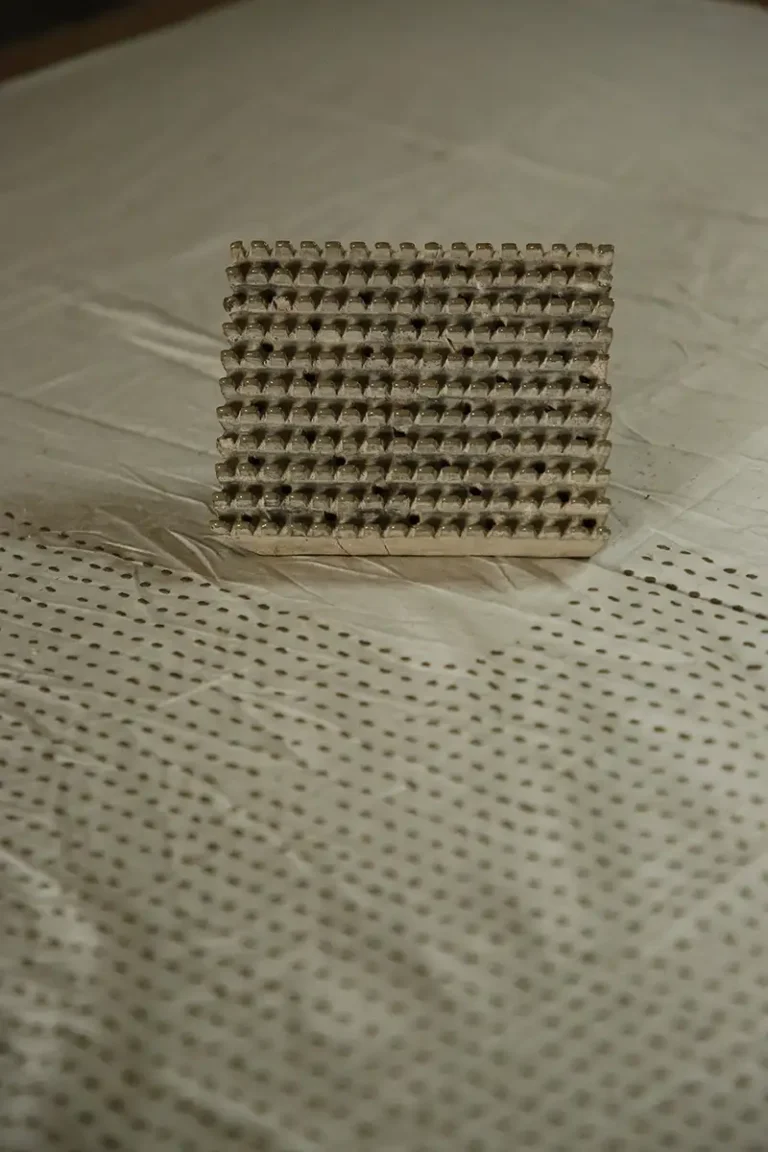

In the modern day, blocks are most frequently created with wood, linoleum, or rubber. Depending on the intricacy, blocks can take days – even months – to carve. If a pattern with many different colours, elements, and dimensions is to be achieved, multiple blocks may have to be carved, then layered in different colours to create a single image. While this is one form of block printing, our process shows yet another side of the many possibilities!

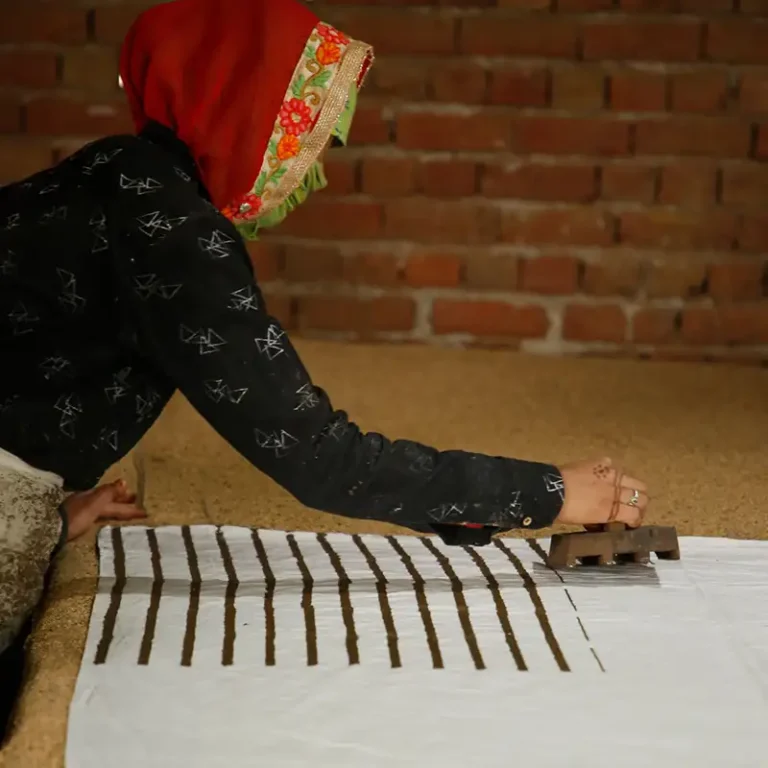

The blocks used for this collection were hand-carved from wood and employed in the ancient Dabu mud-printing technique. It is believed that this method of printmaking dates back to the 8th century in India and continues to thrive to this day.

The word ‘Dabu’ is derived from the term ‘Dabaana,’ meaning ‘to press.’ This is a resist dyeing technique, which works by covering areas of the fabric that are meant to resist the dye, creating the desired pattern.

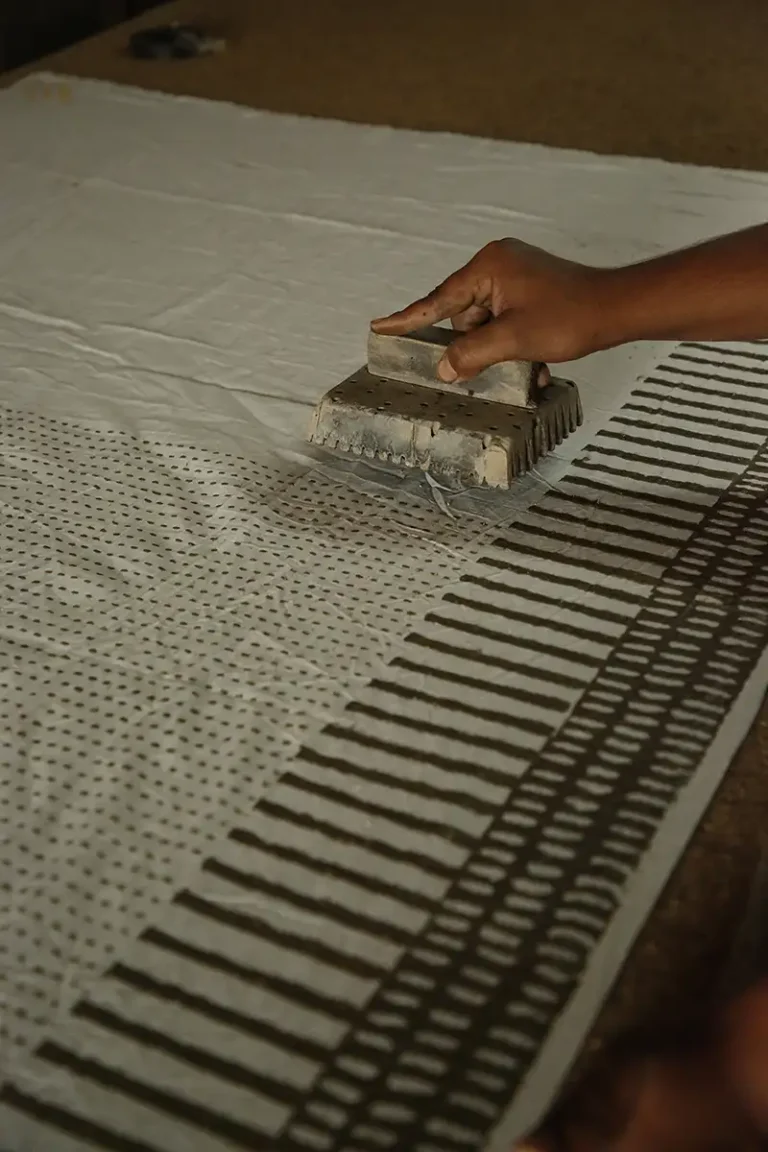

In Dabu printing, the resist is made from a mud mixture containing gum, lime, and white chaff. This mud is carefully pressed onto the fabric using the wooden block. Once the block printing is complete, the fabric is left to dry naturally before moving on to the next stage.

Moving forward, the fabric is dipped in an indigo vat. At this point in the process, you really get to see how a resist dye technique works. Any place on the fabric that has been covered in the mud through block printing will not absorb the indigo dye. This creates a pattern with the natural fabric beneath.

If you’re interested in seeing the indigo dyeing process from start to finish, follow this link to watch our DIY tutorials! And if you want to go back even further, click here to read about how natural indigo is grown and harvested – you may be surprised to find that these beautiful blues come from a green plant!

After the fabric is dipped in the indigo dye, the fabric is washed thoroughly in order to fully remove the mud, and the pattern appears, clean and complete! As you can see, block printing can achieve an amazing effect, all from one small pattern!