INDIGO HARVEST AT THE TARAI BLUE FARM

During our trips to India, friend and frequent collaborator Kiran Sandhu. welcomes us to Tarai Blue indigo farm, where we’re able to witness and participate in the indigo harvest first hand. We recorded every step to share with you. Read on to learn about an indigo harvest from start to finish.

If you haven’t read about Kinny’s indigo farm and journey yet, you can click here for more info. Or read on to learn more about the indigo harvest, and how this sustainable process leads to the eco friendly garments in your closet.

Part 1: The Indigo Plant

In this blog, I’ll be sharing our experience of the first time we were able to visit out collaborators in India and see the indigo harvest, which began on the 1st of September 2022.

We went over to Tarai Blue Indigo Farm to watch their first indigo harvest of the season. Kinny’s farm is located in Uttarakhand, and the community of artisans that she has gathered here is amazing. So much knowledge of indigo and traditional practices in one place.

At the point when we arrived, the process of growing indigo was already underway. The seeds for the indigo plant were sown directly into the ground roughly 4 months previously, then watered once a week.

The type of indigo plant that is grown here is indigofera tinctoria, and it is no coincidence that it thrives here in the planes below the Himalayas. The indigo plant grows about 7 to 8 feet high due to the rainfall and very fertile soil in this region: the perfect conditions for an indigo harvest to thrive.

I refer to indigo dyeing as magical on a pretty regular basis, and the plant itself is no exception. Bugs hate it, it doesn’t need any fertiliser, it doesn’t need copious amounts of watering (which cuts back on excessive water usage) and it puts back nitrogen into the soul. When it comes to sustainability, it is easy to see why indigo pigment is great for the environment.

PART 2: CUTTING THE INDIGO

With the indigo plant at this significant height, the field is chopped down to about 4 ft to allow for new growth. This means that in 6 to 7 weeks, the leaves will be chopped and harvested once again.

The team at Tarai Blue is mainly female, and it is amazing to see them cut the indigo branches off quite roughly with scythes… I did ask to have a go!

Once chopped, the indigo is piled up into a trailer and taken to the weighbridge so that its weight can be recorded. Tarai Blue keep extensive records of each indigo harvest and its yield so that they can follow how each year compares.

Watch the video here to see the Tarai Blue team chopping and harvesting the indigo plant, or take a look at our gallery of the indigo fields below…

Part 3: Beginning the Extraction

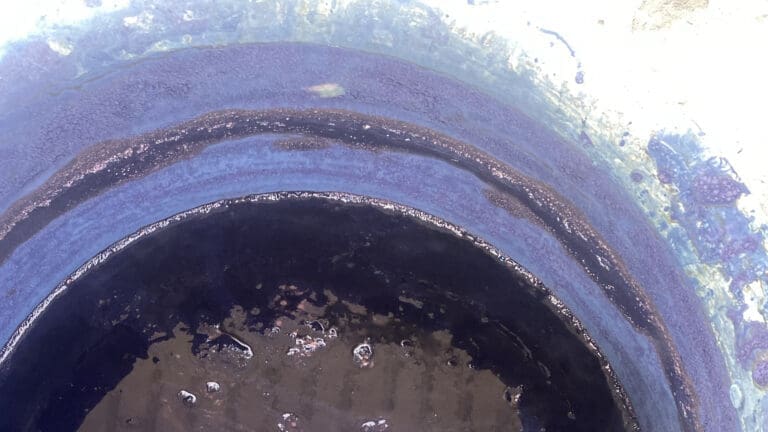

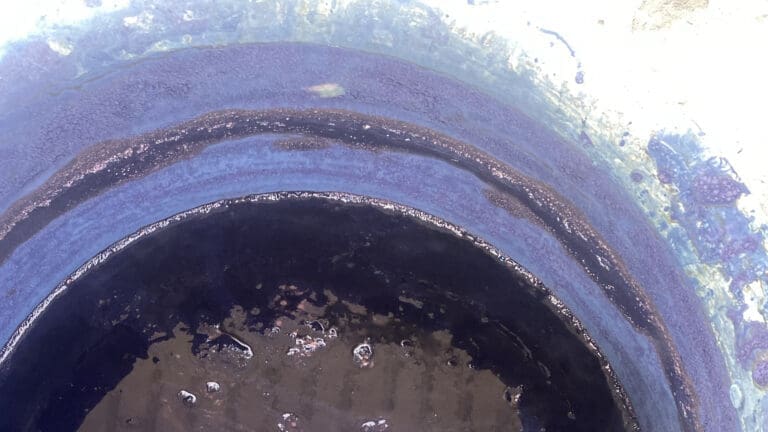

In this next step, the cut down indigo leaves and stems are loaded into 1000 litre water tanks. These have been repurposed from the farm, the lids chopped off so that the indigo can be bundled in.

The tanks are then filled up with water and big rocks placed on top to weigh down the leaves. This keeps the indigo leaves submerged under the water’s surface, where they are left to ferment. This can take up to 24 hours in this incredibly hot time of year.

Shankor Mandal keeps a close eye on the development so that he knows the perfect time to drain off the water and begin the next extraction stage. Notice the beautiful combinations of greens and blues in the water!

Part 4: The Extraction Process Begins

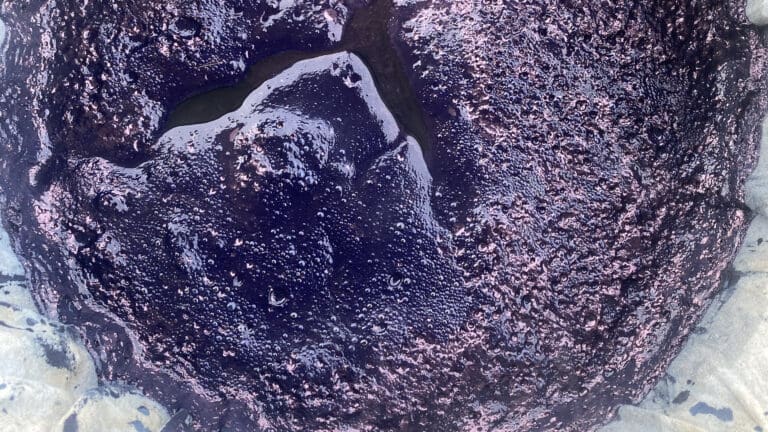

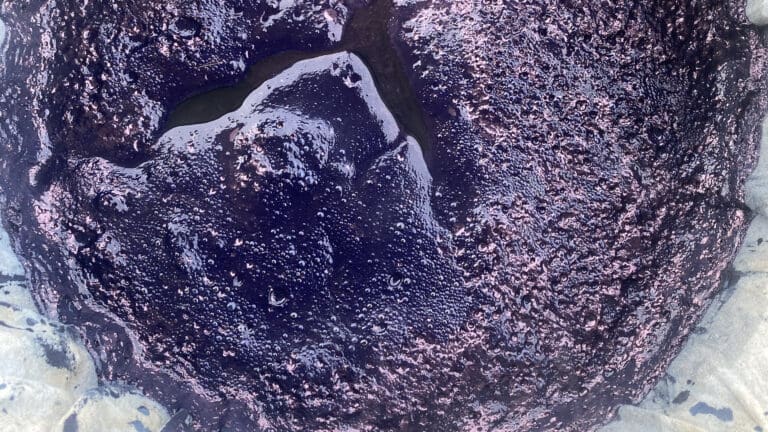

The next stage is where all the action happens: the indigo extraction process.

The green/turquoise colour of the water that you see in the images means that the indoxyl has appeared from the fermented leaves. This means that it is time for each tank of fermented indigo water to be drained off through taps and out into barrels below.

Take a look through the gallery above, or watch this video to see the process in action…

Aerating the Indigo the Tarai Blue Way

Now the process intensifies. Tarai blue have developed their own unique way of aerating their indigo, which they’ve come to over a few years experimenting. They landed on this unique method of using long handled naturally woven baskets that can efficiently add air into the barrels with a fluid motion.

This whole aeration process takes roughly 30 minutes for each barrel.

Once the bubbles dissipate, the aeration is complete. You can tell that this is happening as they make a slightly fizzing sound and then the surface goes still. These barrels are now left to settle for 1-2 days so that the pigment can sink to the bottom.

Part 5: Reducing Indigo Down to a Paste.

During the few days that the barrels are left to settle, all the indigo pigment sinks to the bottom. This leaves a clear, slightly yellow colour on top of the water, which is then carefully drained off and the indigo sediment scooped out into large cooking pots.

Once the indigo is in the pots, it is lifted onto an open wood stove and brought to the boil for about 1 hour. It is stirred constantly, then allowed to cool.

The indigo is then gently poured through cotton strainers, as you can see in the image here.

At Tarai Blue, the giant strainers are fashioned out of laundry baskets, which act as racks to hold the cotton as the indigo is poured through.

One big cooking pot is divided into 6 strainers, then allowed to sit in the shade and slowly drip through any excess water.

This is where the process really slows down and gets intricate. The success of the indigo extraction is all down to the indigo cook: in this case, Shankar’s eye and knowledge.

Once the cotton strainers have been hung for 1-2 days, all the excess water has naturally dripped away to leave a condensed sticky blue paste, which looks a bit like very soft glistening butter.

Each of the strainers are weighed, which continues Tarai Blue’s meticulous record of the yield for each season’s crop and cut.

Part 6: The Drying Process

To start the drying process, Shankor sets up square wooden frame tracks onto a table in the sun, covered with a heavy weight of cotton. Each bundle is then unpeeled, spread out evenly, and levelled into each rack.

It takes about 6-8 hours in the scorching Indian sun for the indigo paste to firm up, which allows it to be divided evenly.

The colour of the indigo paste is the most deep rich hue I have ever seen. All the facets of the indigo’s blues and purples are just out of this world, glistening and catching the sunlight. It really does look like blue gold.

The End of our Indigo Extraction Story

Once the indigo paste has dried down, the texture is a bit like a cookie dough. At this stage, it is firm enough to slice up into blocks that once dry, will be about 100 grams on average. Once cut and separated to allow for drying individually, each indigo block is imprinted with the distinctive Tarai Blue logo and left to fully dry out naturally in the Uttarakhand air.

Witnessing and getting to help a bit with in this fascinating process of natural indigo blue dye extraction has been an absolute eye opening experience. So much time and care is taken into every stage of this ancient indigofera tinctoria plant extraction.

You can buy the very Tarai Blue indigo that was made in these photos on our website

You can also read more about the Tarai Blue Indigo Farm RIGHT HERE.